1

/

of

5

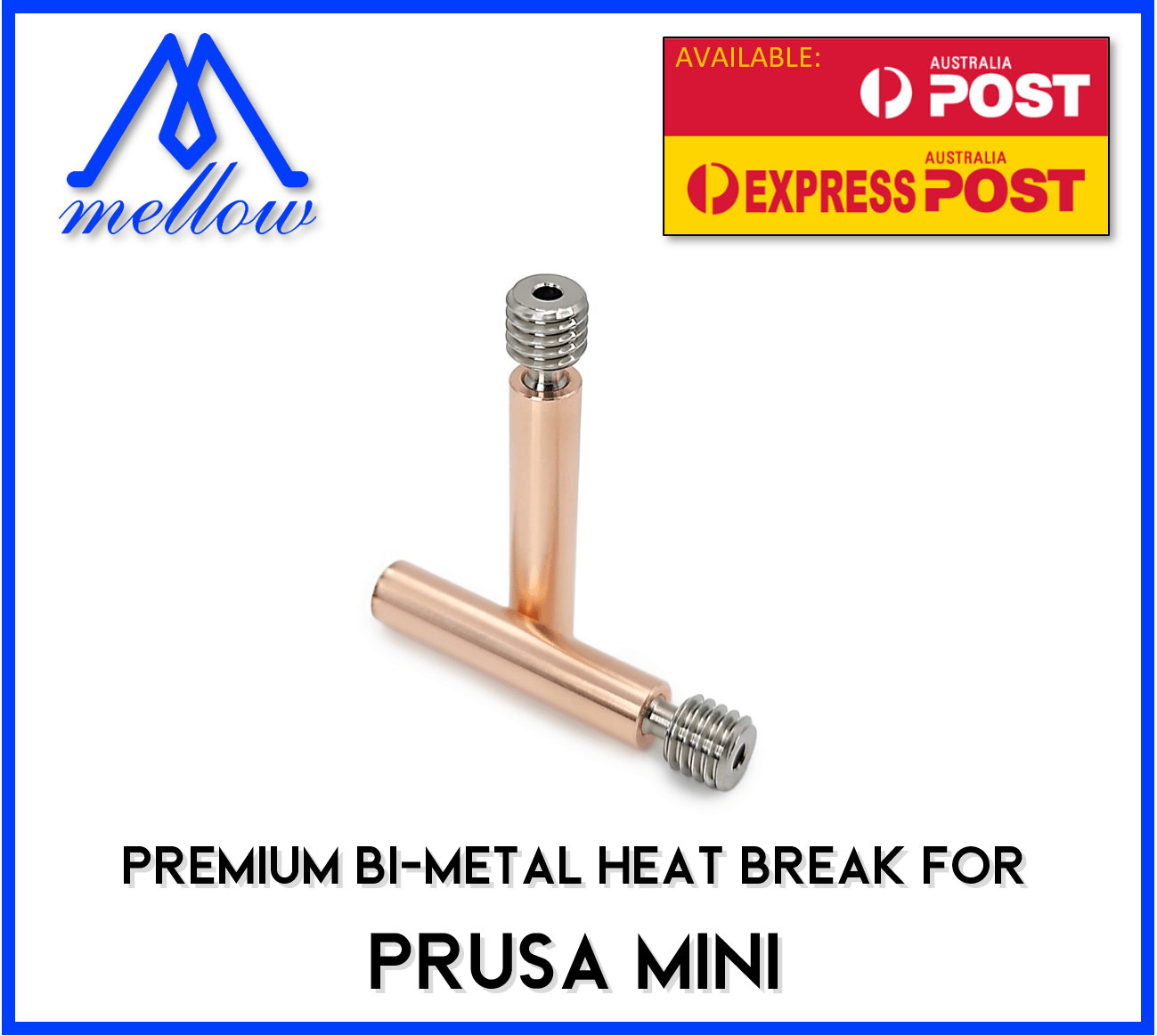

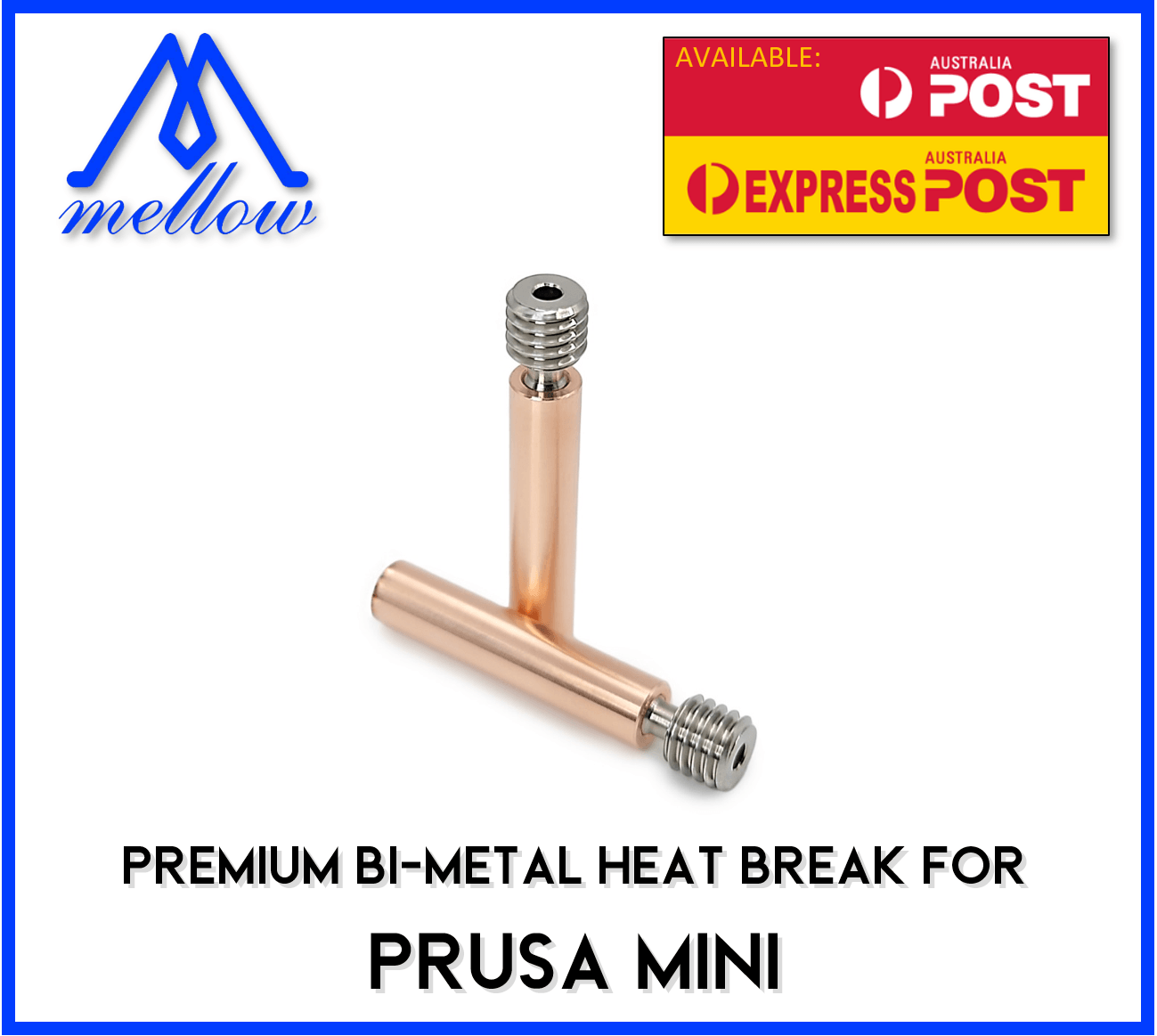

Prusa MINI Heat Break Bi-Metal Titanium Alloy and Copper - 1.75MM Heatbreak

Prusa MINI Heat Break Bi-Metal Titanium Alloy and Copper - 1.75MM Heatbreak

Regular price

$16.99 AUD

Regular price

Sale price

$16.99 AUD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

Prusa MINI Heat Break Bi-Metal Titanium Alloy and Copper - 1.75MM Heatbreak

(bi-metal) COPPER & TITANIUM ALLOY (Grade 5) HEATBREAK FOR PRUSA MINI x1 Unit

PLEASE NOTE: As this Bi-Metal upgrade has a longer thermal break to reduce PTFE tube degradation you may need to adjust/cut down your current PTFE tubing

Compatible with;

- Prusa MINI

- or Compatible variations

Why grade 5 Titanium & Copper?

Using a titanium heat break can help with 3D printer performance, by helping keep the the "cool side" of your hot end cooler. With the smooth (Polished) all metal throat it can reduce clogs. Titanium has the best strength to weight ratio of all known metals, giving you conference in its reliability.

Along with Titanium's ability to reduce heat entering the "cold zone" of the hotend, the Copper component help dissipate any heat quickly. Well made Bi-Metal Heatbreaks a typically known for performance improvements and heat creep reduction or elimination.

Our heatbreaks are a premium upgrade option and there is a lot of non genuine titanium CNC / 3D Printer accessories out in the market. Titanium has some unique properties of which may help assist you, if you would like to make sure you have a product made from titanium. Titanium is typically non-magnetic and approximately 45% lighter and steel (Stainless steel is often use to mimic titanium).

Thermal paste is recommended on the long section of the heat break when fitting. (Supplied) . Please see the manufactures/suppliers instructions of your hotend for more information on why and how to apply.

PLEASE NOTE: Thermal Paste supplied has a Max operation temp of approx. 240-250 degrees Celsius (464F), we suggest using a high performance paste on throat/heat break if you intend to use elsewhere than the long threads, typically this would only apply if the paste if used on the "hot side" of your hot end of which, in most cases is not recommended.

We currently stock titanium or bi-metal versions of most common heat breaks. Please check our other listings if you are interested.

Share