1

/

of

4

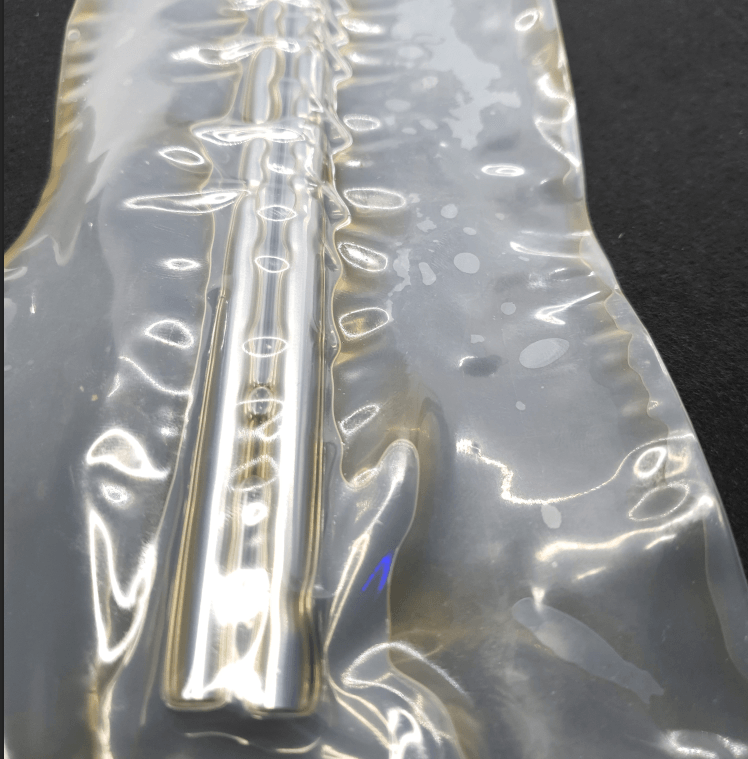

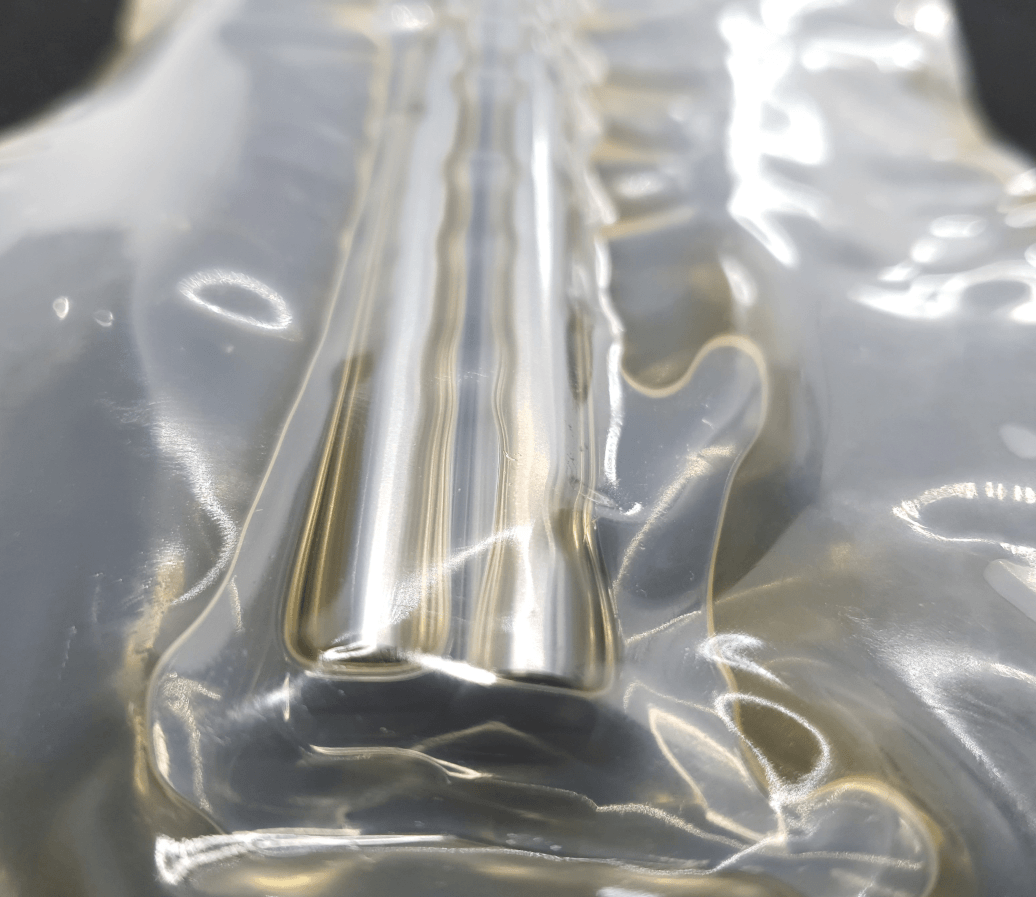

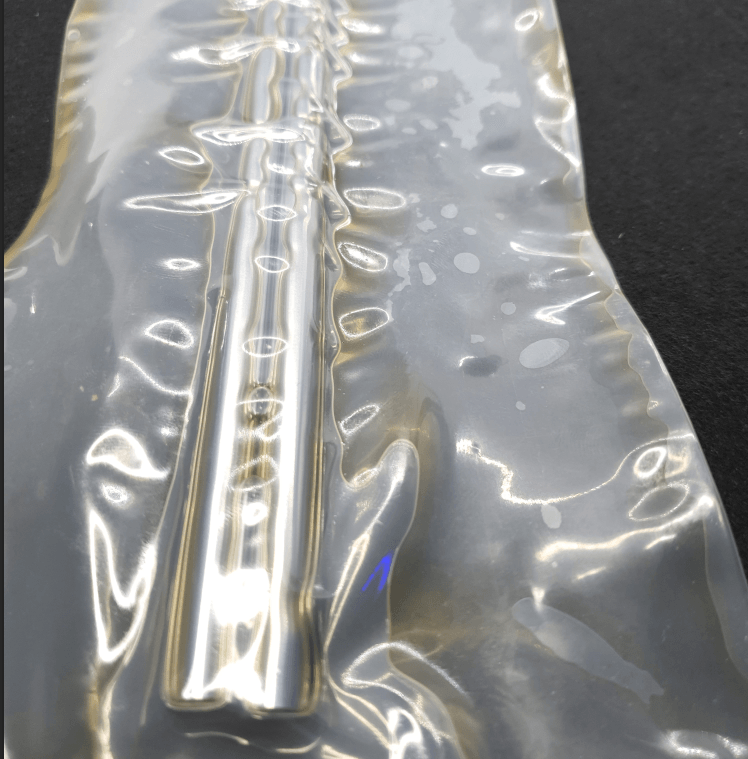

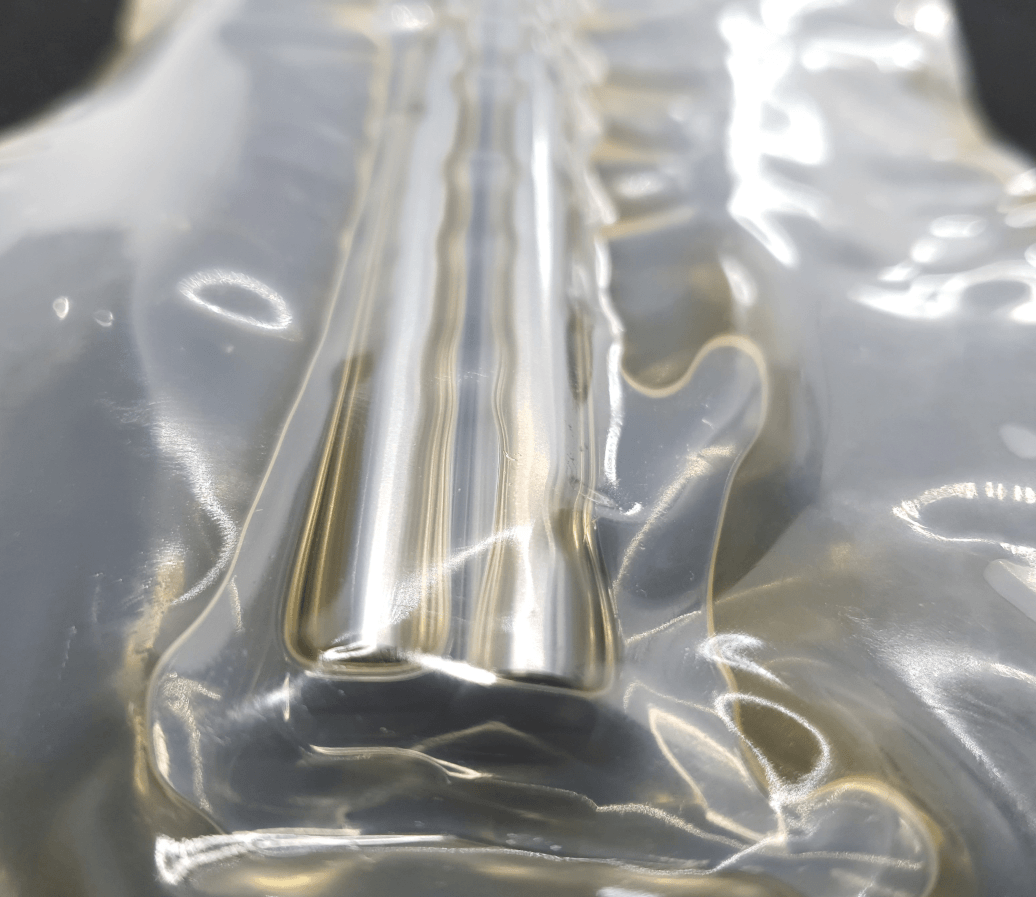

MISUMI Smooth Rods PSFJ8 8mm Hardened Chrome g6 58HRC 2pcs 3D Printer CNC Prusa

MISUMI Smooth Rods PSFJ8 8mm Hardened Chrome g6 58HRC 2pcs 3D Printer CNC Prusa

Regular price

$34.47 AUD

Regular price

Sale price

$34.47 AUD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

- Upgrade shafts for 3D printer / CNC with 8mm linear bearings.

- Ideal Replacement for lower quality rods that tend to wear.

- Prusa 3D Printer X, Z and Y Axis Available (See below for sizes)

Can increase print quality on 3D prints by reducing play, running smoother, and quieter than cheaper linear shafts.

Premium linear shaft upgrades are among some of the most popular upgrades on 3D Printers and CNC Machines along with linear bearings.

Specifications

- Make: MISUMI

- Type: PSFJ8

- Material: SUJ2 Equivalent Steel

- Length: 320 / 330 / 370 / 450 / 500 mm (L) (depending on selection)

- Shaft Diameter (Ø): 8mm (D)

- Hardiness: Induction (58HRC~)

- Shaft Tolerance: g6

- Surface Treatment: Hard Chrome Plating

- Prusa Specs: 370mm (X Axis) / 330mm (Y Axis) / 320mm (Z Axis)

G6 Tolerance

The G6 Tolerance, is one of the most ideal balances for linear shafts where accuracy is required. The play is reduced to unnoticeable, all while still allowing for margin or error. Be it from the bearings or by the design and build of the machine it is attached to. Cheaper made shafts will not compare and when paired with MISUMI bearings, can be premium upgrade.

Additional information

Linear Bearings are designed to ride on smooth rods directly which can cause unwanted results if the bearings or the rods themselves are not suited to each other.

If upgrading your bearings, it may be advantageous to upgrade your rods also to match your bearing tolerances. It is also recommended to check your rods for spalling (Flat grooves made in rods from bearings).

When installing linear bearing on a horizontal aligned rod, it is best to follow the manufactures recommendation on the orientation of said bearings. This may be either with two ball "races" riding on the rod or one ball race. If you cannot find any manufacturer information, we recommend the bearings are seated with two races riding on top of the rods.

Please note that while most bearings are oiled during the manufacturing process this is typically used as a rust prevention is most cases and we highly recommend a application of aftermarket lubricant before using any linear bearing of these types. Maintaining your bearings with grease/oil periodically is also ideal to prevent undue wear or any performance issues.

We use Superlube PTFE oil or grease when required. But other common use lubricants can be just as effective, though these should not be used before conducting your own research as some lubricants may cause damaged or have little effectiveness.

Share