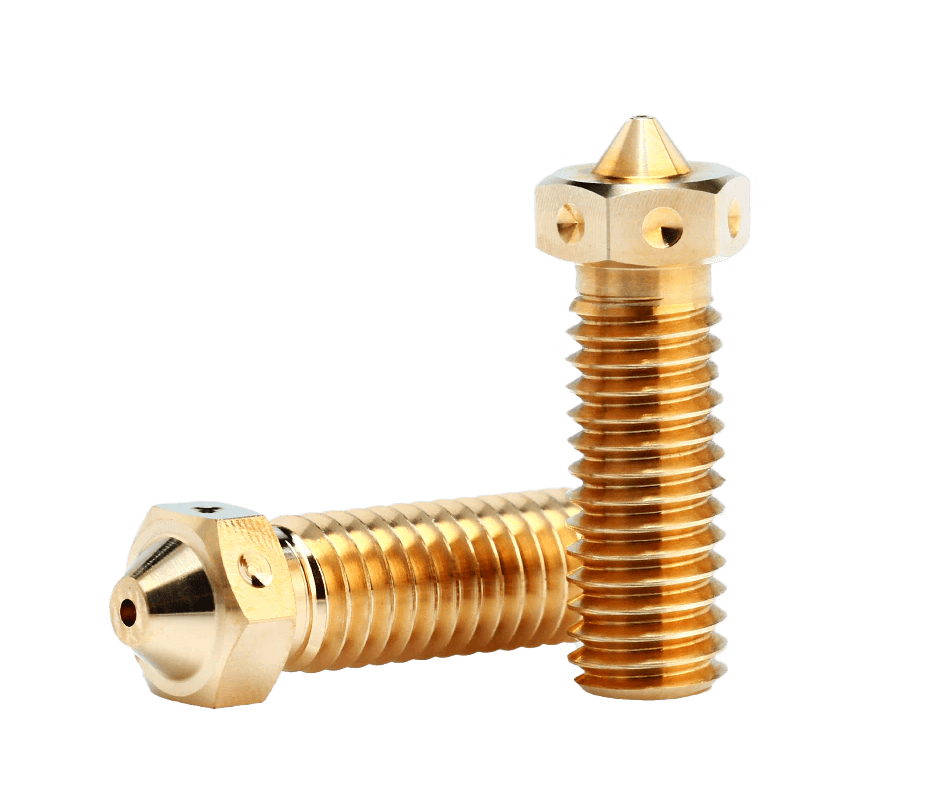

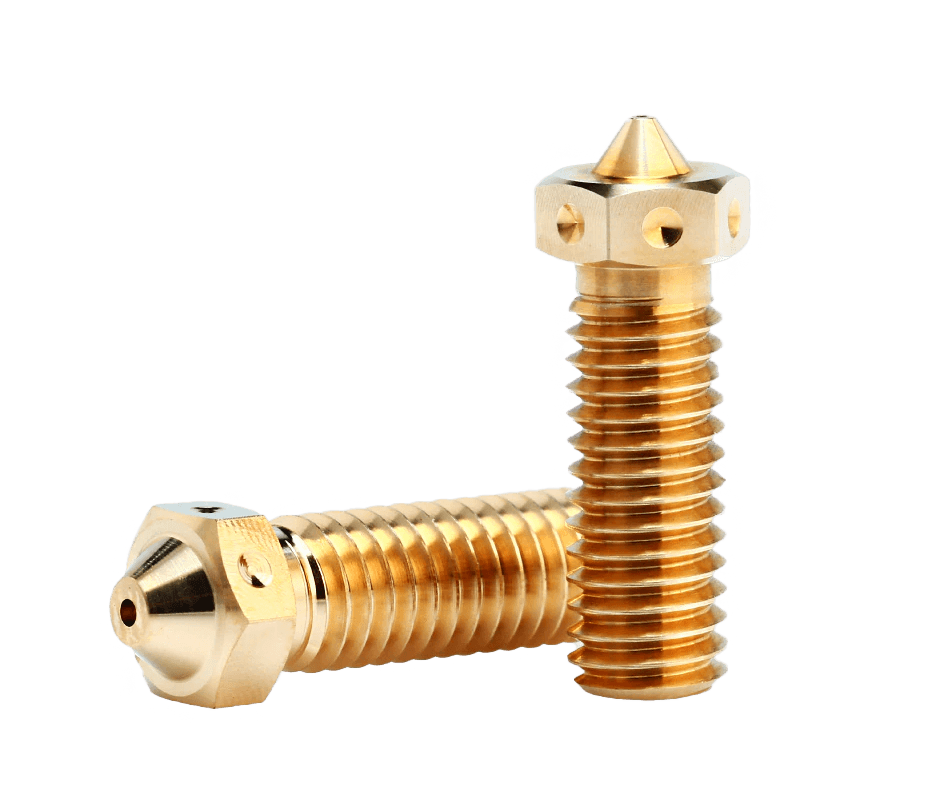

Brass E3D Volcano Compatible Triangle Lab High Quality Nozzle

Brass E3D Volcano Compatible Triangle Lab High Quality Nozzle

Couldn't load pickup availability

- Volcano E3D Style Hotends

- Volcano Heater Blocks

Triangle Labs high end brass nozzles

Triangle-Labs manufacturing process closely follows OEM specifications/drawings and is machined from a top quality brass alloy on a 5 axis CNC and then the aperture drilled precisely. Leaving a accurate centred and smooth filament path. These Triangle-Lab nozzles are designed to give you the best print result possible.

It has taken us a long-time start selling V6 brass alloy nozzles and this is because most are poor quality and in a industry where many parts look alike, we wanted to provide the best brass nozzle we have access to and after much testing we are now proud to be supplying Triangle-Labs high end brass V6 nozzles compatible with E3D V6 hotends, Mosquito Hotends and many more aftermarkets options.

As many of you are aware, we pride ourselves in providing quality products and not just random 3D Printer parts in the market. These nozzles are no exception.

Are brass nozzles right for your application?

When comparing brass alloy 3D printer nozzles to hardened nozzles, there are a few advantages that brass nozzles offer that you may want to consider.

Thermal Conductivity: Brass has higher thermal conductivity performance compared to hardened materials like tungsten carbide or hardened steel. The higher thermal conductivity of brass allows for better heat transfer from the heater block to the nozzle, enabling somewhat more efficient melting and extrusion of filament.

Filament Compatibility: Despite not being a super hardened alloy, brass nozzles are still very compatible with a wide range of filaments, including most commonly used materials like PLA, ASA, ABS, PETG, and more. Though, some hardened nozzles are more suited for specific filament types, such as abrasive or very high-temperature materials but these brass nozzles will handle temperatures up to 300°c

Cost-Effectiveness: Brass is generally less expensive than hardened materials like hardened steel or tungsten carbide. This cost advantage makes brass nozzles a more economical choice, especially for hobbyists or users who don't require extreme durability or resistance to abrasive filaments.

Please note that not all nozzles are created equal and while you may find hardened nozzles at a cheaper price than some brass nozzles, this, in most cases will be at a cost of quality of which may create more problems than it fixes.

Hardened nozzles have their own advantages in certain scenarios but may not add any extra benefit vs cost if not needed. For example, if you plan to print with highly abrasive filaments (glow in the dark is some of the most abrasive) and materials like carbon fiber-filled filaments or metal-infused filaments, a hardened nozzle made of materials like hardened steel may offer superior wear resistance and longevity.

Ultimately, the choice between a brass alloy nozzle and a hardened nozzle depends on the specific requirements of your 3D printing applications. If you primarily work with standard filaments a brass alloy nozzle can be a suitable and cost-effective option. However, for specialized applications with abrasive or high-temperature materials, a hardened nozzle may be more appropriate.

Share